Marcin Lukasiewicz, Dariusz Bogdal

Department of Polymer Science, Politechnika Krakowska,

ul. Warszawska 24 31-155 Krakow, Poland

e-mail: [email protected]

| Abstract | Keywords | Introduction | Experimental | Literature |

Abstract

The employing of tetravalent chromium oxide (Magtrieve™) in

oxidation of some simple alcohols and hydrocarbons under microwave

irradiation were shown. Many advantages of such new oxidation protocol

comparing to conventional heating and using another oxidants were pointed

out.

Keywords

Magtrieve™; microwaves; oxidation

Introduction

Microwave processing of materials offers distinct advantages over

conventional heating in some applications [1]. The

energy of the microwave field can be dissipated directly into the desired

media, without the convection and conduction associated with conventional

heating [2]. The

introduction of microwave energy into a chemical reaction which has at

least one component which is capable of coupling strongly with microwaves

can lead to much higher heating rates than those which are achieved

conventionally [3].

Additionally the reactants do not interact equally with the commonly used

microwave frequency for dielectric heating and consequently selective

heating can be achieve [4]. Since

early eighties there is a lot of reports on conducting organic

transformation in the presence of microwave fields. The oxidation reaction

are also a part of these investigation (using permanganate, dichromate,

hydrogen peroxide, persulphates and others oxidant [5]). Magtrieve™ is DuPont's trademark for the oxidant

based on tetravalent chromium dioxide (CrO2) [6]. Scheme 1

Scheme 1

In our research on oxidation

processes, we chose Magtrieve™ as an oxidant, because it has been proven

to be a useful oxidant in some reactions including the oxidation of

alcohols [7]. Magtrieve™ as an oxidant is very well suited reagent

for microwave synthesis, because as an ionic and magnetically retrievable

material, it carries a benefit of so efficient converting of

electromagnetic energy into heat according to dielectric heating

mechanism. Scheme

2

Scheme

2

The investigation were focused on the oxidation of

alcohols to corresponding carbonyl compounds (illustrated on Scheme 1 by

example of 2-octanol) and side-chain hydrocarbons to equivalent ketons

(illustrated on Scheme 2 by example of fluorene).

Experimental

All experiments were carried out in multimode and monomode

microwave reactors (Plazmatronika Poland). The reaction procedure

involves simple mixing of 1g of the substrate (alcohol or hydrocarbon), 5g

of Magtrieve™ and 20mL of toluene. The heterogenic mixture were placed in

the reactor and irradiated during specific period of time (see Table 1)

under reflux. The power of applying microwaves were set in order to keep

the reaction mixture boiling. After completing of the reaction the oxidant

were separated by the magnet and the solvent were evaporated resulting the

crude product which was purified by distillation or crystallization.

Result and Discusion

As a result we have obtained a number of desired

carbonyl product showed in the table 1 and 2.

Table 1. Microwave oxidation of alcohols by Magtrieve™

Substrate

Product

Yield [%]

Time [min]

![]()

![]()

99

25

![]()

![]()

73

30

![]()

96

5

65

20

![]()

![]()

85

30

The satisfactory yields of conducted reaction shows that Magtrieve™ is an

useful microwave-working oxidant. Because its ionic structure and magnetic

properties Magtrieve™ is strongly coupled with microwave irradiation.

Table 2. Microwave side-chain oxidation of hydrocarbons by Magtrieve™

Substrate

Product

Yield [%]

Time [min]

![]()

54

90

![]()

25

90

![]()

65

70

![]()

86

60

96

45

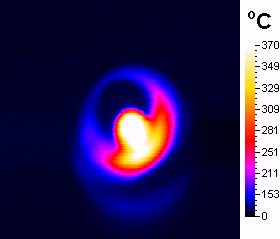

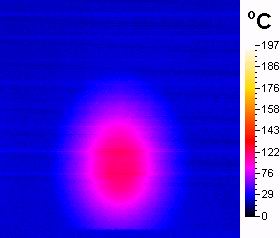

The experiment

of irradiating of pure oxidant showed dramatic increase in temperature of

the material up to 370�C in 2 minutes (Scheme 3) what was mesured by

infrared camera. The addition of nonpolar solvent (toluene) prevents the

substrate to keep of burning (what was observed in additional experiment

where only the liquid substrat i. e. alcohol and oxidant were irradiated)

but the temperature of the reaction mixture after 2 minutes of irradiation

reaches the boiling point of the solvent and the surface of the oxidant

has about 140�C (Scheme 4).

Scheme

3.Pure Magtrieve™ after

2minutes of irradiation

Scheme

4.Reaction mixture after

2minutes of

irradiation

In conclusion we

can say that, however we have used a transition metal (chromium) oxidant,

the describing procedure is environmental friendly because of short

reaction time, easy set-up and separation of oxidant. Additionally the

recycling of the oxidant (described in literature) ranks the described

method of oxidation as a powerful and "green" tool in modern organic

synthesis.

Literature

[1]. P. Lidstroem, J. Tierney, B. Wathey, J.

Westman; Tetrahedron; 2001, 57, 9225

[2]. C. Gabriel, S.

Gabriel, E. Grant, B. Halstead, D.P. Mingos; Chem. Soc. Rev.; 1998,

27,213

[3]. H. M. Kingston, J. S. Haswell; "Microwave-

Enhanced Chemistry. Fundamentals, Sample Preparation and Applications";

American Chemical Society, 1997

[4]. L. Perreux, A.

Loupy; Tetrahedron, 2001, 9199

[5]. a)D. Bogdal, M.

Lukasiewicz; Synlett, 2000, 1, 143 b) R. Varma, R. Saini, H. Meshram;

Tetrahedron Lett.; 1997, 38, 6225 c) R. Varma, R. Saini, R. Dahiya;

Tetrahedron Lett, 1997, 38, 7823 d) R. Varma, R. Saini; Tetrahedron Lett;

1998, 39, 1481

[6]. a) US Pat. 4 524 008(1985) b) US Pat

3 278 263(1966)

[7].R. Lee, D. Donald; Tetrahedron Lett;

1997, 22, 3857